Beam Layout Welding Yellow

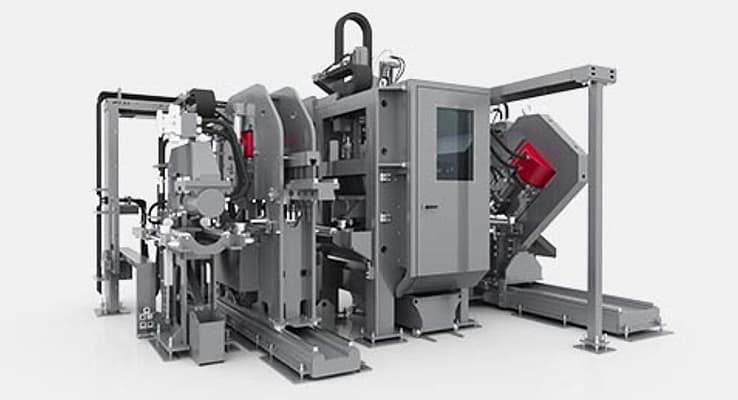

On the opposite ends of the web, the two flanges are placed on a conveyor section. They are then rotated to the vertical position and held in place by magnetic guide rollers. The three pieces are moved against a retractable stop, and hydraulically clamped in the correct relative positions. They are manually joined by the operator. The clamps are removed and the tack-welded beam sent to the welder. After setting the clamp positions for the first beam is done, the operator can control material movement using the control panel for any subsequent beams of the same dimensions.

.jpg)